As we all know, outdoor energy storage power has now become a hot topic, and more and more businesses want to share this piece of cake. Today as a supplier of portable power station whole machine production, we will take you into our laboratory and test workshop to see how many test steps a qualified and safe energy storage power products need to go through before leaving the factory.

The safety of outdoor power supply is crucial both for customers and for manufacturers. As the company that manufactures portable power station, we also highly more pay attention to it. That's why our energy storage power supplies are required to pass these eight tests strictly before they leave the factory.

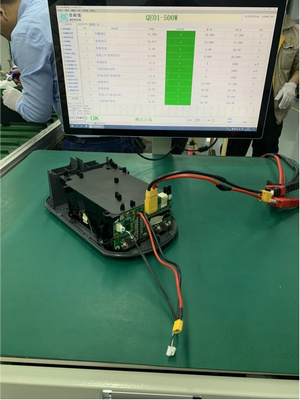

1、BMS test

The main role of BMS testing is to improve battery utilization, prevent battery overcharge and overdischarge, extend battery life and monitor battery status. In other words, it is a system for managing, controlling and using battery packs.

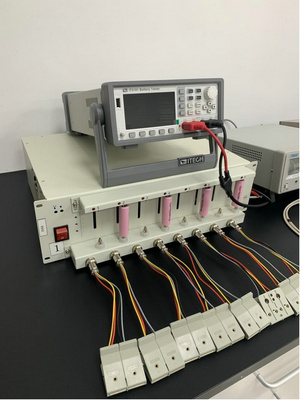

2、Battery Pack Testing

A battery pack is a battery group formed by connecting many independent electrochemical units in series. Sometimes there are quality problems due to various factors, and the quality is not up to standard for the power supply is a big hidden danger, so the battery pack test is particularly important. The main test is the voltage, current, internal resistance and other items inside.

3、Battery cell testing

The core test is mainly to conduct the following seven tests, including capacity, normal temperature charging and discharging, multiplier, pinning, high and low temperature aging, storage, transportation and other tests to ensure the normal operation of cells.

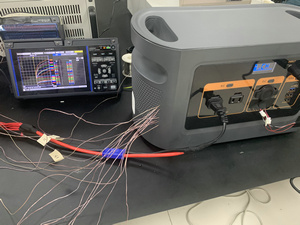

4、Load testing

The purpose of load testing is to determine and ensure that the energy storage power system will operate properly despite exceeding the maximum expected workload. In addition, load testing evaluates performance characteristics, such as response time and other time-related aspects.

5、Temperature test

By means of a temperature test machine, a temperature test is performed on the inside of the energy storage power supply to ensure proper operation in high/low temperature environments.

6、Temperature rise test

The part of the power supply that can be touched when working, if the temperature is too high may cause personal injury, and too high a temperature inside the device will also affect the performance of the product, or even lead to a decline in insulation level or increase the mechanical instability of the product. Therefore, in the product design process, the temperature rise test is an important step to consider to ensure that the product can work safely and stably.

7、High and low temperature test

This test is mainly used to determine the adaptability of the energy storage power supply in high or low temperature climate conditions of storage, transportation, use, because the power supply in the manufacture, handling or storage applications will face a variety of different temperature and humidity, climate and external conditions and other impacts.

8、Aging test

We have a professional aging room in the energy storage power supply industry, conduct aging test for each outgoing energy storage power supply to improve the reliability of the product.

The original energy storage power need go through so many layers of steps of testing before leaving the factory, if you are also interested in other, welcome to continue to pay attention to our next update. Echom technology, portable power station ODM one-stop service provider.